No less than 13 (!) different motors made by different manufacturers, controlled by one compact PLC and centrally regulated with the help of just one touch panel? Sounds incredible – but it is a fact in this current project of the business unit Automation technology of our subsidiary Berghof Automation. Non-proprietary systems and open CODESYS standard are the magic words.

The name says it all: Under the telling motto “We make automation simple“, the Swedish company Scandinavian Drive Technologies (SDT) has made a very good name for itself as a specialist in the automation of machines and systems throughout Scandinavia. SDT is specialized in motion applications with servo drives.

For many years, the business unit Automation technology of our subsidiary Berghof Automation – a pioneer in the field of industrial automation and currently the talk of the town thanks to its new, industrial-grade Raspberry®-based systems – has been one of SDT's most important technology partners. There is a very simple reason for this close partnership: “My customers want maximum performance within minimum space and without any technological shackles caused by proprietary technology – and thanks to Berghof, I am able to provide them with exactly that,“ SDT managing director Lars Radler explains why he has consistently relied on Berghof for many years when it comes to controllers and operator panels.

The benefits of this congenial interconnection for plant engineers manifest themselves, for example, in the “Floating Capper“ automatic capping machine with which the Swedish company Trepak, market leader for automatic filling and capping systems for liquid products in Sweden, Norway and Denmark, is setting new standards in its field.

For the “Floating Capper“ seals bottles without the conveyor belt having to stop as is the case with conventional systems (see video). This novelty has two advantages: Firstly, the particularly high performance of 90 closures per minute and secondly, the significantly minimized risk of spillage and, consequently, contaminated containers.

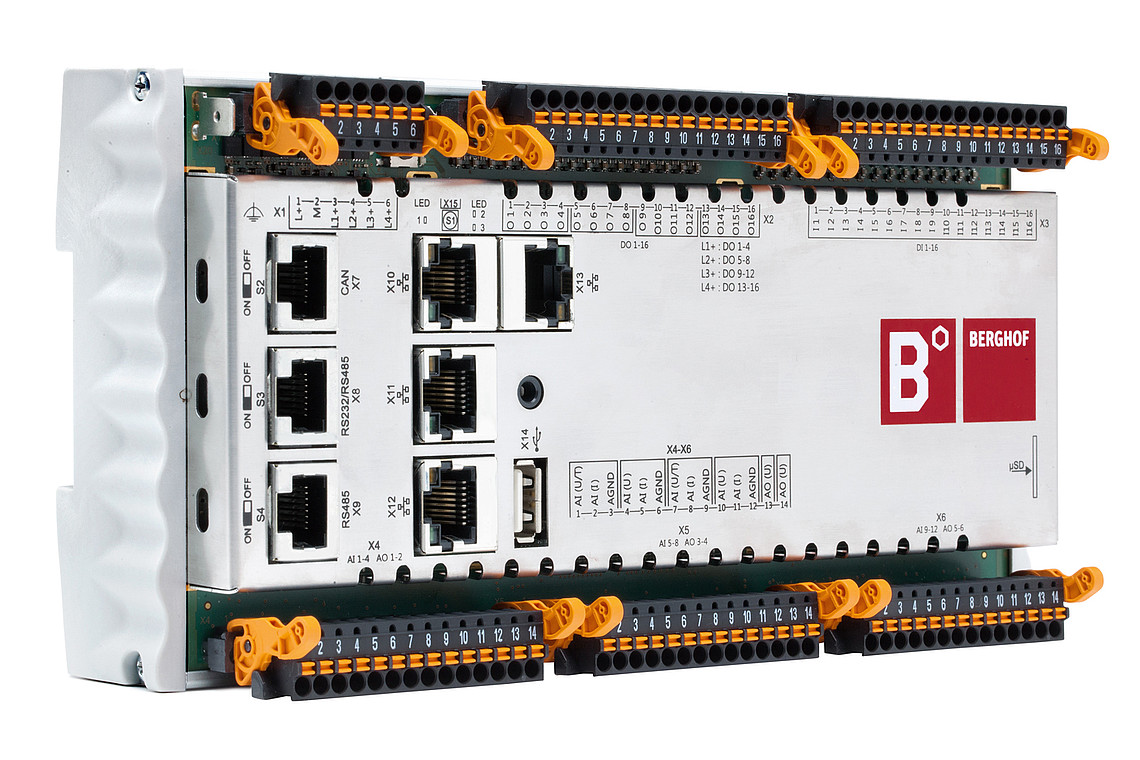

To ensure that everything at the “Floating Capper“ is in flux in the truest sense of the word, no less than 13 (!) servo motors made by different manufacturers are used. Nevertheless, SDT and Berghof have managed to control this varied and technically complex mixture with just one controller, the compact powerhouse Berghof B-FORTIS CC-Prime based on “EtherCat“.