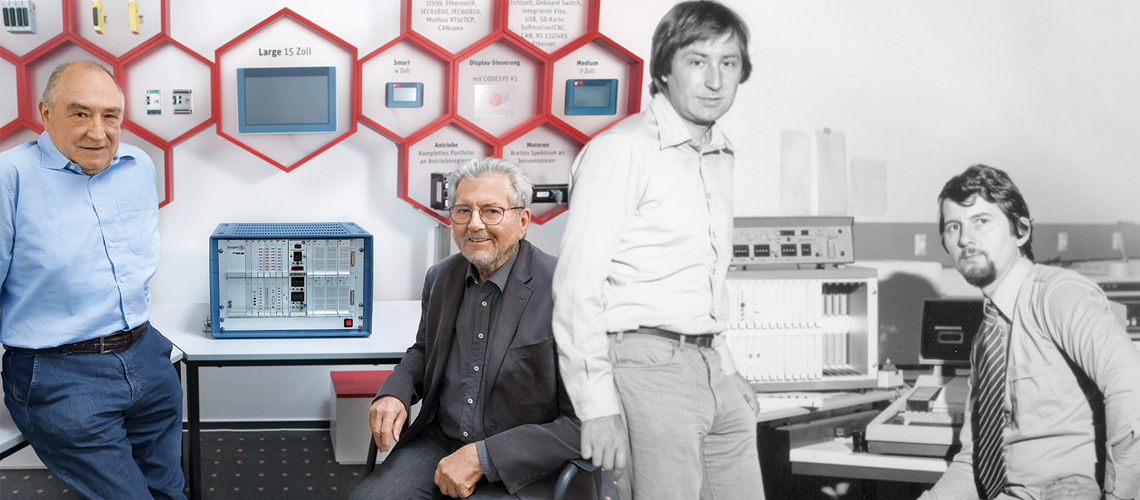

Friedrich Arnold (left) and Richard Häußermann, the driving force behind the Berghof Automation company for many years, were the ones to bring the first freely programmable microprocessor controller "FPS 76" for industrial applications onto the German market in 1976 - and with it, completed a true pioneering step. We look back at this event together with them. And review the exciting development of this first smart industrial controller through to the smart factories of today.

As it is popularly said: When the mountain doesn't come to the wise man, then the wise man goes to the mountain. Which is why these Berghof employees spontaneously decided to personally visit Intel in the USA in 1976 in order to see the first demo version of the "I8080", the first complete microprocessor in the world.

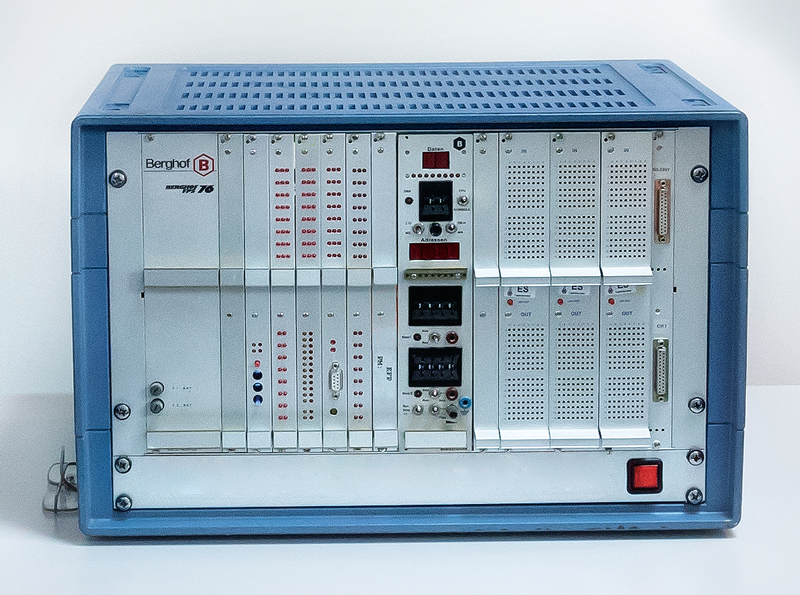

"Whoever wants to be ahead of their time cannot hesitate long," commented Richard Häußermann, shrugging his shoulders in reference to this expensive procurement measure. He and his team had a clear goal: The I8080 was to become the core piece of the first freely programmable microprocessor controller for Germany's industrial applications. The Berghof experts had already made contact with Intel at a presentation tour in which Intel managers had presented their future plans to selected companies - and were truly electrified by the completely new possibilities that the Intel microprocessor would open for them. Their vision: "We wanted to make it possible for an industrial controller to be cycled parallel for different tasks for the first time using the integrated operating system," Friedrich Arnold remembered. Just a short time later, the Berghof developers made this vision reality - and proudly present their work to the amazed experts: the FPS 76. In the first sales brochure they listed the groundbreaking new possibilities fairly soberly and objectively, as is common for technicians: "The FPS 76 implements any logical links, counting and time functions, memory and shift registers as well as arithmetic functions".

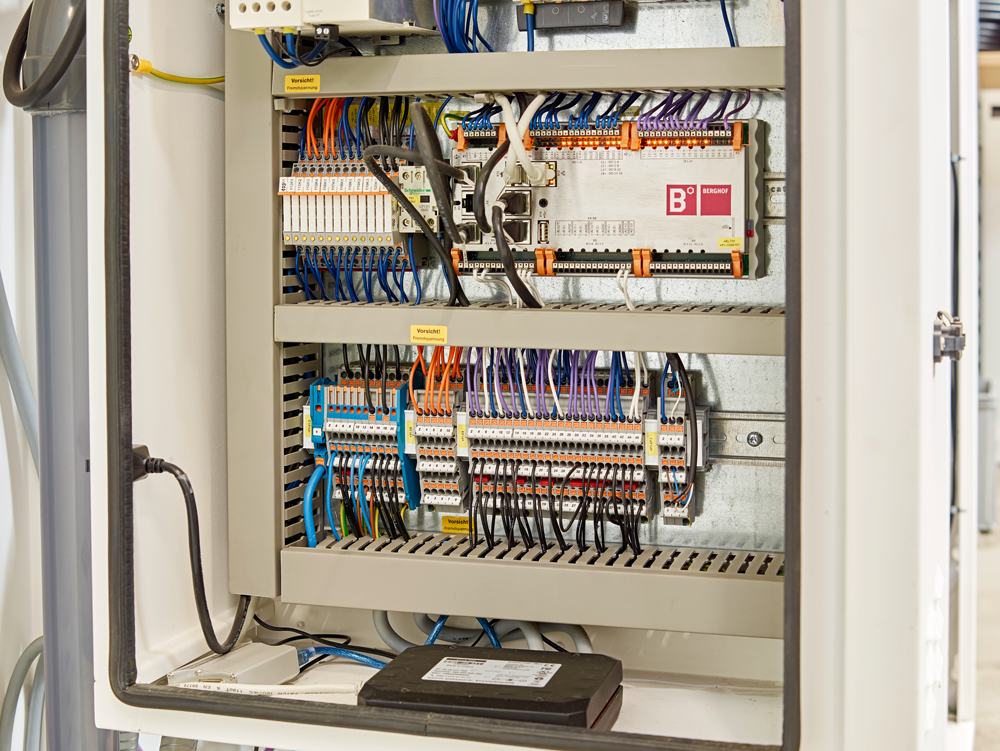

Today we know: What sounded so unspectacular was nothing less than the big bang moment for a technology that has completely revolutionized the industry - Programmable Logic Controllers (PLCs). Programmable logic controllers play a central role in current discussions about the Internet of Things, the ever-increasing digitization of industry - keyword: Industry 4.0 - or the construction of production plants that can be dynamically adapted to changing requirements - keyword: Cyber-Physical Systems (CPS) - due to their great flexibility and easy integration into industrial control systems. Berghof Automation's new claim is not just the proverbial spark, but a whole lot of truth - "Pioneering Automation Technology".