In October 2020 Germany celebrated the “German Unity Day“ and the reunification of Germany for the 30th time. For the Berghof Group, this special anniversary has also particular significance: It marks the very birth date of a business unit, that has become an important part of our group of companies today and has been operating successfully and internationally from Mühlhausen in Thuringia – Berghof Process Management.

Taking a closer look at the history of Mühlhausen in northwest Thuringia one will soon

realize that electronics has a long tradition here. Even in the 1950s, specialists in the medieval Imperial City did a lot of tinkering already, first with tube technology, later with pocket calculators and microcomputers.

Just a few weeks after the fall of the Berlin Wall, these electronics specialists from the East

exchange ideas with representatives of the Berghof Group for the first time. What becomes quickly apparent after the first joint projects: the chemistry is right, and the companies are determined to become close partners on equal terms. So the successor company to VEB Mikroelektronik and the Berghof Group decide to unite their strengths and know-how in a joint venture - and the success story of Berghof Process Management begins.

This joint venture quickly develops into a successful alliance. As a consequence, the Berghof Process Management business unit, now part of Berghof Automation GmbH, grows sustainably and becomes firmly established in various areas. For example, in the market where the company first gets a good reputation - in railroad technology. In 1997, it developed a first control system for Deutsche Bahn (DB) in Cottbus, and just two years later the second control system in Frankfurt – for the fundamental modernization of which Berghof was recently awarded another contract.

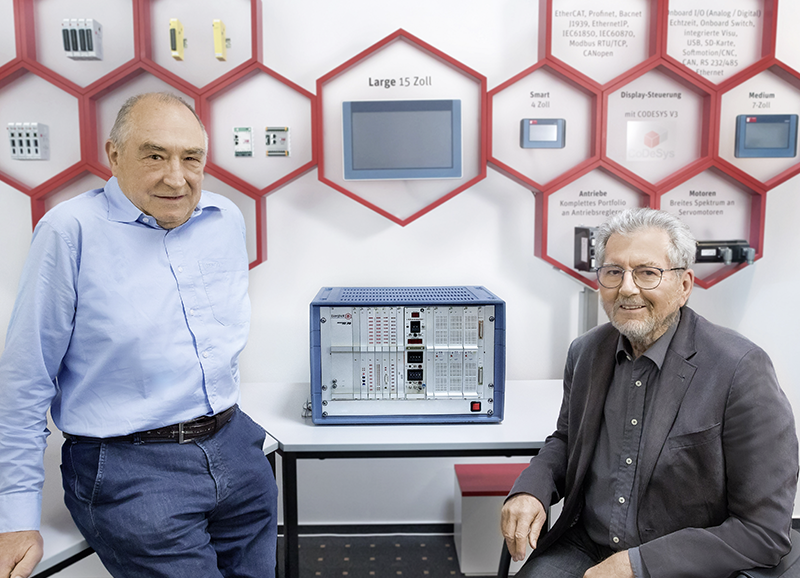

By its holistic focus on process and security optimization, the Berghof Process Management team has tapped into more and more application areas over the years. Our company founder Prof. Dr. Georg Zundel realized early how important committed and innovative employees are for the success of all Berghof business units: “Without our capable and reliable employees it would have been impossible for me to be entrepreneur and scientist at the same time“.

A good example for the strong team performance of Berghof Process Management: The operations control system “IBIS“ especially for maintenance plants, with which maintenance and repair work on trains can be excellently planned and executed. Based on this system, the team in Mühlhausen masters a very special challenge in 2017 – the “BFR“ (operations control computer) as the central control system for Europe’s largest and most modern

railroad maintenance factory in Cologne-Nippes.

“In this important prestige project, we prevailed in a major international tender against everybody who’s anybody in the field of control technology for railroad systems. This shows what a good reputation we have built up over the years at DB,“ says Thomas Wallstein, who has headed the division since the beginning of 2019 together with Annett Lange, thanking the team of Berghof Process Management for its tireless efforts.