That Joscha Sontheimer found himself working for our subsidiary Berghof Fluoroplastics, the experts for innovative material solutions made from the high-tech plastic Polytetrafluoroethylene (PTFE), in his vacation after school finals was more or less an accident. It is no accident at all, however, that the young father found his professional fortune here after studying and has become an important pillar of the company within about only five years. In this interview, the enthusiastic mountain-biker explains why the title Development Engineer does not fully describe what he does, why working with PTFE repeatedly fascinates him and why he also values good planning and a structured approach in his private life.

1) You worked for Berghof Fluoroplastics for several months right after your A-levels. How did that come about?

I didn’t want to start studying straight after school but wanted to take part in an international voluntary project in the field of nature conservation in Nevada (USA) first. For that, I needed the necessary cash, of course. A schoolfriend than gave me the tip that Berghof Fluoroplastics is always on the lookout for helping hands – and he was right. That I was going to spend several months there was not exactly the plan but it turned out be just the right thing for me. I wanted to study process technology after my stay in the USA anyway and for that, I was able to gather valuable experience of different materials and processing methods such as isostatic moulding, one of our specialities at Berghof Fluoroplastics.

2) What made you decide to return to Berghof Fluoroplastics a few years later after graduating from university?

I had enjoyed doing casual work at Berghof Fluoroplastics back then. Everyone here really works hand in hand for common goals, every new team member is received with open arms and soon feels part of the team and warmly welcome. I was impressed by how the “old hands” readily passed on their technical knowledge and immense wealth of experience to the younger generation – and always had a sympathetic ear for their ideas and suggestions. So, I stayed in close contact and chose my major fields of study for my bachelor in process technology and my subsequent master’s degree in “Design & Development for Automotive and Mechanical Engineering” (DDM) so that I am able to work for Berghof Fluoroplastics as a broadly qualified engineer in different departments. Once I had my master’s degree in the bag and then got back in touch, the management thought it over and soon after offered me the opportunity to join the team in the Research and Development department as a development engineer. I accepted immediately of course. Today, about five years later, I can say: A very wise decision!

3) Polytetrafluoroethylene (PTFE), the main material at Berghof Fluoroplastics, is considered by experts to be a real multi-talent. What makes this high-performance polymer so special in your opinion?

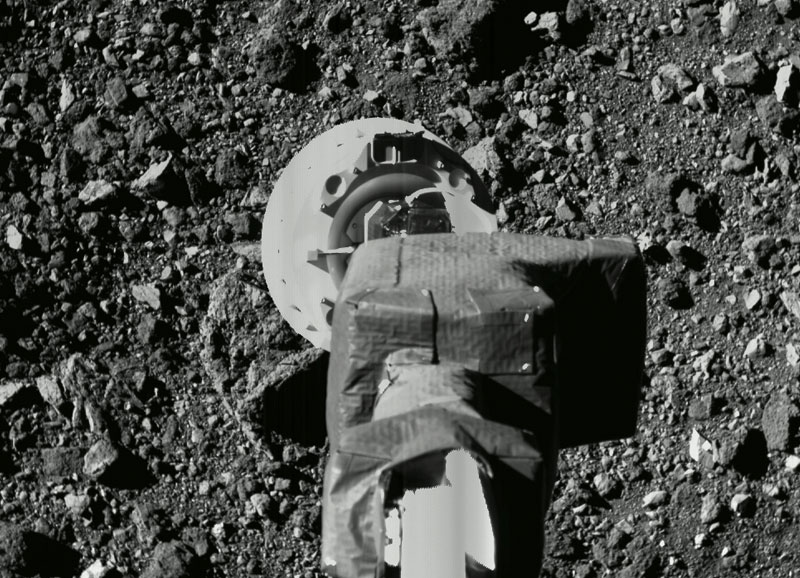

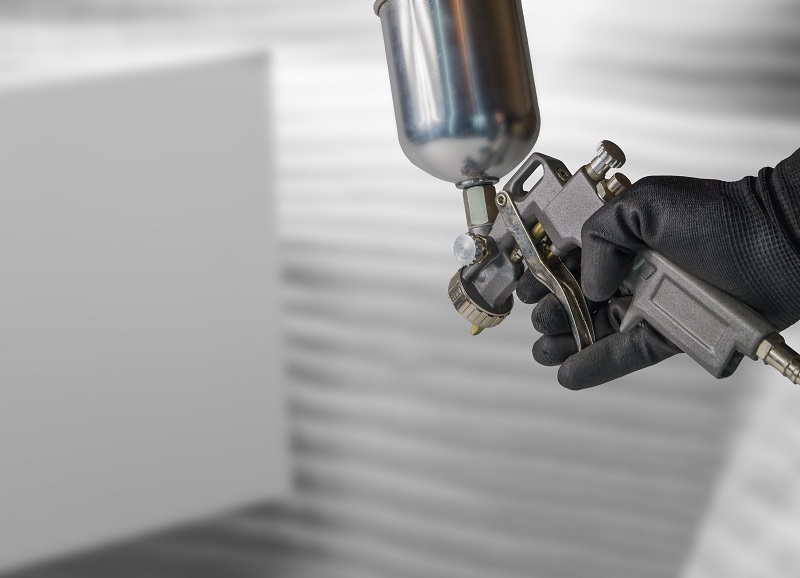

PTFE is definitely one of the most versatile, if not the most versatile material at all. That is what makes it so special – and the work for us as a team so extremely interesting and varied. Because, in the field of photonics, our specially developed optical PTFE Optopolymer®, for example, is used for quite different reasons than our porous PTFE Permeaflon® in the automotive industry, to name just two important examples. Depending on the application, quite different properties tip the scales for PTFE – such as, for example in laboratory applications, the unique temperature or chemical resistance and the extremely anti-adhesive properties or the virtually unlimited UV and weather resistance. Therefore, we are repeatedly faced with quite different challenges in our projects – and our team needs a lot of mental flexibility and the will to continuously learn something new in order to understand applications exactly and transform them into material solutions fit for series production. I can think of no other material which covers a similar application range – from radar-based filling level measurement in biogas plants or grain silos to pure white integrating spheres in photonics – and at the same time sets absolute standard in all industries.