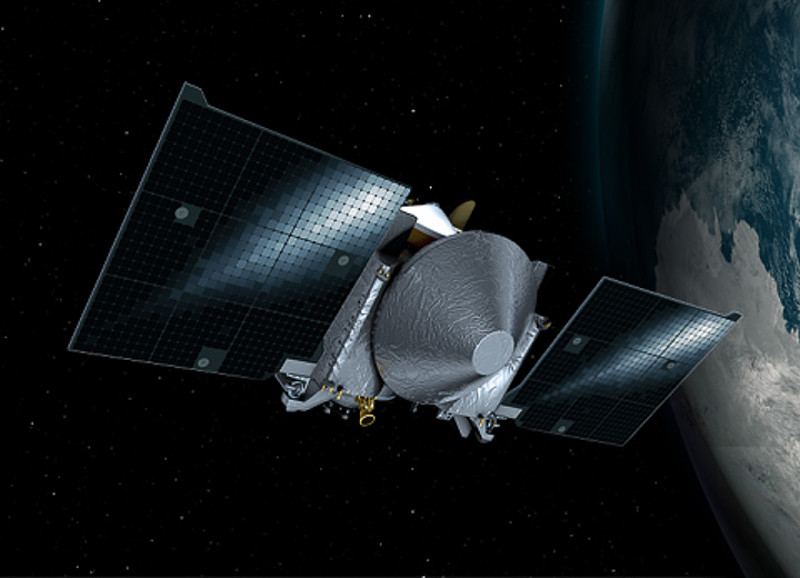

Almost as thrilling as the moon landing: A great number of people all over the world were spellbound when they followed the NASA live stream and watched the satellite “OSIRIS-REx“ landing for a few seconds on the asteroid “Bennu“ sucking in material from the surface with its grab arm. Our subsidiary Berghof Fluoroplastic Technology GmbH made a significant contribution to the smooth running of the maneuver.

A few years ago, when the inquiry flaps into their email inbox, the employees of Berghof Fluoroplastic Technology GmbH can hardly believe their eyes at first: for a new mission, the American space agency NASA is looking for a material to protect highly sensitive measuring instruments from optical radiation – and the organization asks whether the Berghof experts, specialized in superior material solutions made of isostatically pressed polytetrafluoroethylene (PTFE), have the perfect solution for this task.

A few months later, after numerous laborious tests at NASA, one thing is certain: Yes, Berghof does have the perfect material solution – even for this extreme use in space. And this is for good reason: Berghof Fluoroplastic Technology GmbH, a subsidiary of the Berghof Group has been developing PTFE material solutions with specifically optimized technical properties for more than 50 years for customers all over the world and from a wide variety of sectors. With its six companies the Berghof group serves numerous growth markets such as photonics, filtration technology and e-mobility.

PTFE is known to be a real all-round talent and is therefore in big demand in numerous areas of application. This is why material solutions from Berghof Fluoroplastic Technology GmbH are highly valuable to the automotive and semiconductor industries, among others, but also to laboratory and medical technology. However, to obtain a contract for a space mission was a very special challenge even for the highly experienced engineers and technicians.

The extensive preliminary testing being successfully finished, Berghof supplied NASA with several meters of black optical PTFE film, which the NASA technicians then applied extensively to the surface parts of the satellite, in particular the gripper arm (shown in the photo), and to the optical measuring instruments before launch. “NASA was looking for a material that would absorb the light in the best possible way and at the same time reduce its thermal effects in order to minimize disturbing impact by direct sunlight or reflected diffuse light when taking pictures. Our Black Optical PTFE convinced the customer with its ability to absorb at least 98 per cent of the incident light,“ Jonas Nicoll, Director of Sales and Marketing, is pleased by the outcome.